-

GuillermoExcellent! Fast delivery! I like to work with you again!

GuillermoExcellent! Fast delivery! I like to work with you again! -

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us.

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us. -

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration.

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration. -

SjakThat's true we enjoy doing business with you.

SjakThat's true we enjoy doing business with you. -

Kelly MarshLiFong is one of our desired vendors in China

Kelly MarshLiFong is one of our desired vendors in China -

Raimund Schenkคุณภาพสินค้า ราคาที่แข่งขันได้ หนึ่งในซัพพลายเออร์หลักของเราเสมอ

Raimund Schenkคุณภาพสินค้า ราคาที่แข่งขันได้ หนึ่งในซัพพลายเออร์หลักของเราเสมอ

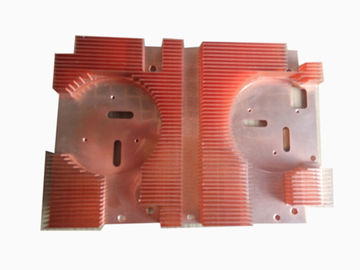

Copper Heat Sinks for Machinery / Computer Cooling Radiator Soldered Fins

| วัสดุ | ทองแดง | ใบสมัคร | เครื่องจักรหรือคอมพิวเตอร์ทำความเย็น |

|---|---|---|---|

| สี | สีเหลือง | OEM | ใช่ |

| ODM | ใช่ | เสร็จสิ้น | Anodizing, Powder Coating, Wooden, Electrophoresis หรือสีใดก็ได้ |

| เน้น | electronic heat sink,aluminum heat sink extrusions |

||

Copper Heat Sinks for Machinery/Computer Cooling Radiator Soldered Fins

Quick details:

1.Material : aluminum, stainless steel, copper, steel,etc.

2.Advanced inspection measure by CMM, gauges, roughness tester, hardness tester,etc.

3.Secondary surface operation: zinc plated, nickel plated, chrome plated, anodize, powder coating, heat

Treatment.

4.Quick delivery.

5.Low quantity are acceptable.

Dimension:140mmx95mmx10mm

Processing Techniques:

1. Aluminum fins: progressive die stamping

2. Aluminum board: extrusion+ CNC machining

3. Copper tube forming: automatic tube bending + burn into tip ends

4. Aluminum board and enclosure nickle-plated, copper fin passivate (insulation, oxidation and corrosion resistance)

5. Assembly: automatic fin wearing/assembly, then fixed by overflow soldering and screw/rivet combination

6. Quality check

7. Packing

Advantages:

1. Professional research and design team, strong and automatic equipments: progressive stamping, automatic tube bending machine, automatic fin wearing machining

2. Strict quality control in each process and finish product quality control

3. Short delivery lead time: 15-30 days

4. Optional for OEM or ODM

5. Comprehensive after-sale service, quick responses for daily communication

Product Images:

![]()

![]()

![]()

Process Capability

| Extrusion | Aluminum alloy and copper alloy extrusion production |

| CNC | Drilling; Milling; Turning; Deep Hole Drilling; Honing; Screw Machining |

| Stamping | Numerical Control Turret Punching, progressive punching. Precision punching |

| Die-casting | all kinds of aluminum alloy and zinc alloy die casting |

| Soldering | Reflow Oven, soldering for Thermal Module heatsink |

| Forge | Pin heatsink for chipset |

| Surface finish | Anodize; Sandblasting, Plated Nickel |

| Assembly | Assembly PAD or grease, hardware, packaging. |

Similar Products Images for Your Reference:

![]()

![]()

![]()